S bend flow meter

Products overview:

ZW - LGW seriesS bend flow meterWith traditional orifice flowmeter as belongs to the category of differential pressure flowmeter, just a way of elbow flowmeter to produce differential pressure and orifice flow meter, orifice is using scaling principle of differential pressure of fluid, and bend sensor is the use of fluid inertia principle of differential pressure.

Both inherited the differential pressure type flowmeter the advantages of simple structure, stable performance, precise measurement, and overcome the differential pressure type flowmeter pressure loss, easy to jam, shortcomings and so on maintenance difficulties.Elbow flowmeter with its outstanding energy-saving effect, high stability, high accuracy, high adaptability, in the heat of the steam, thermal power, metallurgy, petrochemical industry, coal gas, natural gas, hot and cold water, oil, air, acetylene, the media such as h2s, co2 two-phase flow measurement of rapid promotion.

Second, the working principle:

ZW series of LGW s-shaped bend flow meter is when a fluid at a certain temperature under the condition of a certain pressure flow through a pipe, when it flows through a turn, the fluid will make a corresponding circumferential rotary motion.According to the theory of fluid forced vortex, fluid in a circular motion in pipe and solid state operating in the space circular motion, so fluid will inevitably produce inertial centrifugal force, the size of the centrifugal force and flow velocity of fluid, fluid density and a circle of radius of curvature radius of curvature (i.e., bend sensor) and other factors.

Due to bend radius of curvature sensor is known, and through the fluid density and bend sensor can be based on the determination of the parameters such as temperature, pressure of the fluid by host computer accurately, so the size of the centrifugal force generated in a bend on the sensor is just a function of fluid velocity.As long as measure the size of the centrifugal force, it can measure the fluid flow in the pipe, the flow rate multiplied by the cross-sectional area of the pipe and the density of fluid, fluid flow rate can be calculated and determined.The calculation is as follows:

Type (1) through the pipe bending is given the average flow velocity of fluid and the differential value of function:

V = a (P1, P2)/rho beta -- -- -- -- -- -- -- -- (1)

Among them: V - average flow velocity of fluid;

A - the integrated flow coefficient, a = f (bend bend diameter ratio, Reynolds number and power of medium viscosity, pipe roughness, etc.), especially to the influence of the bending diameter ratio zui is important:

P1 and P2 - curved pipe, the lateral pressure difference;

The density of rho - fluid;

Beta - index;

Calculate the average flow velocity V, can function expression for computing the flow:

Q = S * V * rho -- -- -- -- -- -- -- -- -- -- - (2)

Type:

S - bend cross-sectional area;

V - average flow velocity of the fluid.

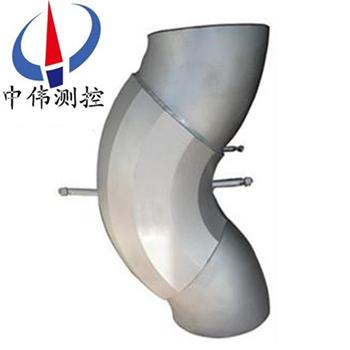

Three, the structure form:

ZW series of LGW s-shaped bend flow meter a sensing element - bend sensor according to the difference of the installed pipeline is divided into the following three:

1, 90 ° bend sensor used for process pipeline in 90 ° Angle joint, to replace the original bend;

2, 180 ° bend sensor used for straight line, straight pipe replacement parts;

3, 135 ° bend sensor used for process pipeline in 135 ° Angle joint, instead of the elbow.

Two small pieces of different bend sensor welding straight call take pressure, bend arc length larger bearing a positive pressure measuring 90 ° and 135 ° bend sensor based on plane which is formed by the installation process pipeline turn subdivided into the following three types:

1, the positive pressure measurement in vertical bend sensor installation - turn on the formation of the plane for the vertical plane and turning elbow arc grew up a party in the above;

2, negative pressure measurement in vertical bend sensor installation - turn on the formation of the plane for the vertical plane and turning elbow arc grew up a party in the following;

3, horizontal bend sensor - turn the formation of plane for level 180 ° bend sensor only horizontal form, other installations meaningless.

Four, structure characteristics and adaptability:

System structure:

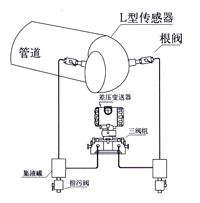

ZW series of LGW s-shaped curved pipe flowmeter is a kind of differential pressure flowmeter, which bend sensor, a secondary instrument or transducer, differential pressure transmitter is a crucial part of the system.Pressure transmitter, condenser, temperature components (can use pt100 platinum resistance or a combination of its and temperature transmitter) according to the working conditions of measuring medium and actual production requirements and appropriate trade-off.Bend is a certain geometry size of 90 ℃ elbow.

Structure features:

1, bend over + 1.5%, the second table has repeatability accuracy + 0.2%, is the basis of measurement results to guarantee high precision tube flowmeter.System measurement precision can be up to + 1.0%.

2, is a kind of energy-saving of the flow measurement device.Wear-resisting bend sensor, stay to ensure stable jobs for a long period of time.

3, can be used directly welded to install, or use flange connection installation, to solve the problem such as "PaoMaoDiLou", greatly reduce the workload of on-site maintenance, save maintenance cost.

Good adaptability:

1, measurable, steam, gas, liquid and other fluid, its ability of high temperature, high pressure, corrosion, even with a small amount of particles in the fluid and floc can also work.

2, can almost work in any complex, poor environmental conditions, such as high temperature, dust, vibration, humidity, such as adverse factors, can work normally, above range than 10:1.

3, to the requirement of straight pipe are relatively low, generally after reaching top 5 D 2 D can work normally.

4, no matter which kind of pipe bending, arc grew up a party for the positive pressure side, by the positive pressure differential pressure transmitter, differential pressure transmitter prospectus medium and labeling) in detail.In fact, bend the installed in the measurement of ninety degrees of corner, its space install state in principle can be arbitrary, that is bend during installation orientation or direction of no strict requirements.

Five, the measured medium:

1, liquid: hot and cold water, chemical liquid, light body oil.

2, gas, blast furnace gas, coke oven gas, all kinds of single-component multicomponent gas.

3, superheated steam and saturated steam.

4, compressed air.

5, natural gas, the torch gas, liquefied petroleum gas.

Six, the main features:

1, no additional resistance loss, save fluid conveying power consumption, to reduce the operation cost;

2, easy installation, no leakage, no maintenance, wear resistance, can be directly installed on the pipeline welding;

3, high temperature resistance, corrosion resistance, good resistance to vibration, shock, resistance to magnetic;

4, strong adaptability, low range wide, straight pipe requirements;

5, high measuring accuracy, good reproducibility;Measuring accuracy can reach more than plus or minus 1%, reproducibility is as high as 0.2%;

6, long service life.

Seven, the technical parameters:

Suitable for special pipes (may be have a wider scope of application)

1, medium: all single-phase fluid, or can be considered a single-phase fluid media such as gas, liquid and steam can be applied elbow flowmeter for flow measurement.

2, pipe diameter, from 25 to 2000 mm (or rectangular pipe).

3, flow velocity, 0.3 ~ 8 m/s (liquid medium), 7 ~ 80 m/s (gas and steam).

4, temperature: 0 ~ 600 ℃.

5, pressure: 0 ~ 10 mpa.

6, the accuracy of measurement: bend sensor repeat conversion accuracy + 0.2% or less, secondary instrument accuracy + 0.2%, bent pipe supporting the use of differential pressure, temperature, pressure transmitter should reach the accuracy grade of + 0.5% more or less accuracy requirement.System measuring accuracy of 0.5 ~ 1.5 on the Richter scale are unlikely.

Eight, the basic composition and function of different parts:

: 1, the bend sensor output rectifier and differential pressure signal, the accuracy of its geometry size is the guarantee of accuracy of measurement.

2, a valve: liquid and gas measurement generally choose straight needle type or Angle valves, steam with high temperature type needle valve or valve welding.

3, drain valve: liquid and gas measurement generally choose two type needle valve, steam with high temperature type needle valve or valve welding.

4, guide pressure pipe: differential pressure transmitter and bend the clamp connection with;Using 14 x2 x3 or 16 of seamless steel tube, the length of parallax pressure transducer and the pipe installation distance surface, usually by the user should bring along their own.

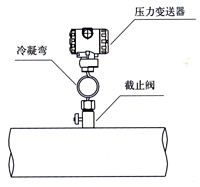

5, disc condenser, steam measurement necessary accessories;Connect to bend sensor, liquid level balance is negative pressure side.

Six, three groups: connected to the differential pressure transmitter, degree to the zero point.

7, differential pressure transmitter: bend sensor measurement inside and outside differential pressure, converted to standard 4 ~ 20 ma current signal.

8, pressure transmitter, superheated steam and other gas measurement, the pressure fluctuation is bigger as necessary;Saturated vapor pressure transmitter can be selected and applied to measure the medium pressure, real-time compensation of flow.

9, temperature components: when the temperature of the measured medium is volatile for spare parts, when used in heating metering, need to choose two component temperature, medium temperature, real-time compensation of flow and to participate in the calculation of heat heating water.

10, secondary instrument (or flow converter) : through signal lines connected with the transmitter, the signal lines: the diameter of 1.0 m ㎡ double Yi shielded cable, its length depending on the transducer and secondary instrument distance, generally by the user should bring along their own.Computing (display) parameters such as flow rate, heat, temperature, pressure, RS232 and RS485 serial interface, can match a computer system, 4-20 ma analog output have or 1-5 v, for the user to choose from.

Nine, installation requirements:

Welding method is used to install the measuring pipe of ninety degrees of corner, install state in principle can be arbitrary, the space that is in the bend sensors as orientation or direction of no strict requirements, generally has the following four install state to choose from:

1, turn level;

2, positive pressure measurement on the vertical installation;

3, positive pressure measurement in vertical installation;

4, any space.

Above four state in principle can be used in pipe installation, but for some of the measured medium, choose the appropriate installation condition, can greatly simplify the installation, debugging, and is of great benefit to improve the system measurement accuracy.So how to choose correct bend sensor installation status is very important.

Ten, use notice:

1, in the high water content of gas measurement, avoid water and pressure into the guide system, cause system can't measure.

In compressed air and fuel gas, many gas such as cracking gas contains a lot of water in the fluid, it is basic in saturated state, some formation water layer at the bottom of the pipe, the conventional installation, water will flow into the inside bend sensor take pressure, pressure into the guide system, the outside also can have a small amount of water into, is in the suction catheter into the water, bring to differential pressure measurement uncertain additional error, should make bend sensor apply pressure on both sides of the body are upward sloping, and boot up pressure tube, connecting the differential pressure transmitter, which avoids the water in the pipe into the guide system, and can make the pressure system in the condensation water flow back to the smoothly, will not affect the measurement.

If consider differential pressure transmitter maintenance is convenient wait for a reason, for differential pressure transmitter has to be put at the bottom of the pipe, can be used with body and guide pressure pipe up first, and then down to avoid a lot of water into the guide pressure system, and the pressure system of zui low tank equipped with set, make guide pressure system of condensation water flow into the liquid tank, drainage regularly, can guarantee the normal measurement.

2, steam flow measurement, pressure system is used to guide pressure with water medium, room temperature water density of 998 kg/m3 (20 ℃), 1 mm water column pressure of about 9.8 Pa, if using traditional condensing tank liquid level as a balancer, the mutation of temperature and pressure in the pipe can break condensing tank balance, cause the liquid level fluctuation, the orifice meter (produced by the pressure difference of about 10 to 100 kpa) effect is very small, but for the bend in small flow measurement may produce bigger effect.

Disc condenser chosen as the liquid level balancer, just make sure when installation disk, vapor and liquid interface at the same level before and after the move, liquid level height is always in the same horizontal plane, played a good level, balancing the instrument after putting-in-service proactively, steam stop delivery, to zero migration of differential pressure transmitter, level can solve the imbalance caused by zero error.

3, there is a small flow problem any flowmeter.Bend while relative other flowmeter performance is good, but still there is a lower limit index (velocity of 5 m/s or higher), so, when choosing diameter bend sensor must ensure zui low velocity is greater than 5 m/s, even though the actual flow rate on the high side, elbow flowmeter in up to 120 m/s the velocity case, still ensure measurement accuracy (adjust range differential pressure transmitter) can be realized.

11, bend flow sensor installation:

Liquid measurement series:

1, the differential pressure transmitter should be installed at the bottom of the bend of the sensor, make the gases in the pressure tube

Get back in the pipeline.If the condition is differential pressure transmitter must be installed above the bend sensor, and a valve connection leads to pressure pipe should be down, and then slowly turn up, connected to the differential pressure transmitter.

Above 2, measured liquid temperature higher than 100 ℃, the root valve selects high temperature type and add the cooling plate.

Gas measurement system:

|  |

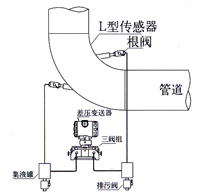

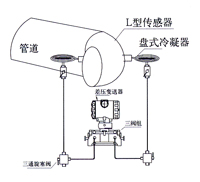

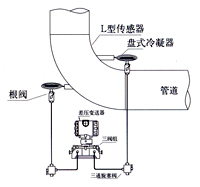

| L sensor in horizontal horizontal pipeline installation | L sensors turn in a horizontal or vertical vertical horizontal pipeline installation |

|  |

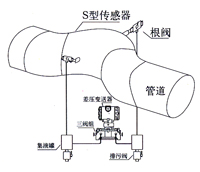

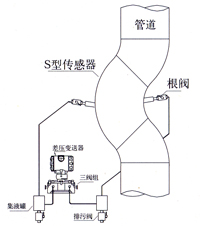

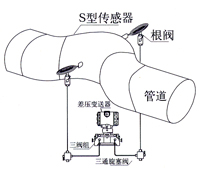

| The installation of S type sensor in a horizontal straight pipe road | S type sensors in the installation of vertical straight path |

1, for installation and maintenance convenience, differential pressure transmitter installed in the pipe bending down to the bottom of the sensor.

2, in order to make the moisture in the gas of less as far as possible into the guide tube, with body tilted upward around 15 ° Angle.

More than 3, measured gas temperature higher than 100 ℃, the root valve selects high temperature type and add the cooling plate.

The steam measurement system:

|  |

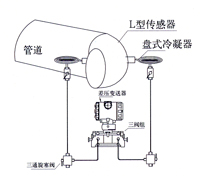

| L sensor in horizontal horizontal pipeline installation | L sensors turn in a horizontal or vertical vertical horizontal pipeline installation |

|  |

| The installation of S type sensor in a horizontal straight pipe road | S type sensors in the installation of vertical straight path |

1, disc condenser disk to level, and take the pressure at the same horizontal plane.

2, differential pressure transmitter should be installed at the bottom of the bend of the sensor, the gas emissions back to the pipe in the pipe.If the condition is differential pressure transmitter must be installed above the bend sensor, the requirements and root valve connection of pressure pipe should be down, and then slowly turn up, connected to the differential pressure transmitter.

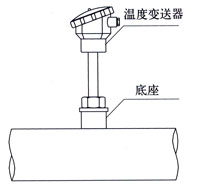

Temperature transmitter installation:

1, temperature transmitter for two wire system 4 ~ 20 ma output.

2, the installation position should be 2 d ~ 5 d bend sensor downstream.

3, temperature transmitter with vertical pipe or sloping direction of fluid flow and the pipe reverse installation.

4, pipe at high temperature, try to stay away from heat flow in pipe by insulation when necessary, make the transducer working environment temperature is lower than 60 ℃.

Pressure transmitter installation:

1, two wire pressure transmitter for 4 ~ 20 ma output.

2, the installation position should be bent pipe sensor is less than 2 d.

3, measured medium is liquid, gas pressure position should be the upper surface of the pipe, apply pressure when the steam measurement location in the side of the pipe.

4, measured medium temperature over 80 ℃, the cut-off valve and transmitter and condensation between curved cooled to below 80 ℃.

Twelve, parameter table:

DN15~2000(For field modification bend sensor, there is no limit to the pipe diameter) |

liquid0.1~12 Steam or gas5~160 |

Plus or minus 1% |

Temperature converter:- 10~45℃ The humidity is less than85% (Special case please specify) |

4-20mA RS-484 RS-132 |

AC220,50HzorDC12~24V |

Liquid: water, oil, methanol, toluene, ammonia, etc Gas, blast furnace gas, coke oven gas, mixed gas, hydrogen, oxygen, air, nitrogen, etc Steam: saturated steam and superheated steam |

Selection code: before the bent pipe flowmeter selection, make sure the following content, and fill out the form below.

(1) the name of the measured medium, medium ingredients or density.

(2) the big flow, small flow, flow, temperature and pressure.

(3) process pipe diameter, wall thickness, material, sensor installation position.

Note: according to the customer's specific requirements, our company can undertake the bend sensor renovation project, for big diameter, users will be decreased and the purchasing cost.

Measuring the dielectric | ||||||||||

traffic | Scale flow | unit | Kg/h - | conditions | Temperature ℃ pressure MPa humidity % | |||||

Heavy traffic | Temperature ℃ pressure MPa humidity % | |||||||||

Commonly used traffic | Temperature ℃ pressure MPa humidity % | |||||||||

Small flow | Temperature ℃ pressure MPa humidity % | |||||||||

Medium density or components | Kg/ m? | conditions | The temperature | ℃ | ||||||

pressure | MPa | |||||||||

Working pressure | MPa | 9 | Install state | The level of - | vertical - | |||||

Working temperature | ℃ | 10 | installation | welding - | Flange connection- | |||||

Pipe diameter | mm | 11 | The sensor type | Ltype - | stype - | |||||

Pipe diameter | mm | 12 | Piping material | |||||||

Transformation of bending diameter ratio (bend is filled) : | ||||||||||

13, selection of coding:

model | Specifications and code | instructions |

ZW-LWG | Bend flow sensor (wei measurement and control) | |

Structural components | A------ | Including the sensor Differential pressure transmitterIntegration of temperature Pressure transmitterAccording to table and valve components |

B----- | Including the sensor Differential pressure transmitterIntegration of temperature According to table and valve components | |

C----- | Including the sensor Differential pressure transmitterPressure transmitter According to table and valve components | |

D---- | Including the sensor Differential pressure transmitterAccording to table and valve components | |

E---- | Including the sensor According to table and valve components | |

According to table type | 1 - | According to table swing in tray |

2 - | According to table vertical plate | |

3 - | A display table of hanging table | |

4 -- -- -- -- -- | Flow switch card | |

The sensor type | L---- | LType of sensor |

S---- | SType of sensor | |

T---- | Special form the sensor | |

G---- | Pipe sections of sensor | |

Processing way | 1 - | machining |

2 - | Push the system | |

Sensor material | 0 - | 20 #Ordinary carbon steel |

1 - | Stainless steel material | |

2 - | Special material | |

Measuring the dielectric | -S | liquid |

-Q | Ordinary gas | |

-M | The gas | |

-Z | steam | |

The sensor diameter | - | See the nominal diameter code table |

14, nominal diameter code table:

A | 20 | J | 125 | S | 600 |

B | 25 | K | 150 | T | 700 |

C | 32 | L | 200 | U | 800 |

D | 40 | M | 250 | V | 900 |

E | 50 | N | 300 | W | 1000 |

F | 65 | O | 350 | X | 1100 |

G | 70 | P | 400 | Y | 1200 |

H | 80 | Q | 450 | Z | st131200 |

I | 100 | R | 500 |

15 order, design notes:

When you place an order, please provide the following conditions in order to help the correct choice of the specifications of the flowmeter and coefficient.

1, pipe size: diameter x wall thickness (mm);

2, measuring medium name: medium density (kg/m3);

3, set the flow range: meter range of upper limit and lower limit (kg/h or m3 / h);

5, work pressure (Mpa);

6, work temperature: (° C);

7, such as wei in my company, please provide together: intelligent flow totalizer.especially pressure range, or pressure transmitter type, range;Temperature range, or models, range temperature transmitter.

After-sales service commitment:

1, from the date of signing of the contract, I in the way provided for products of the company offers free maintenance and maintenance service, commitment to lifelong maintenance service;

2, jiangsu wei measurement and control instrument co., LTD. Sales manager will be in regular contact with customers, understand the usage of products, and solve the problems of the customers to use in the process of produce, free of charge to provide technical support;

3 the man-made damage is found, the warranty period, our company is responsible for the maintenance, and the resulting maintenance fee;

4, product quality problems or are not satisfied with product, the user can choose unconditional return, wei tt&c don't charge any fees, appear quality problem, bear the freight back and forth.